Will Mech Robots Revolutionize Factories—Or Replace Human Workers?

🏭 The Factory Floor Dilemma: Repetition, Risk, and Rising Costs

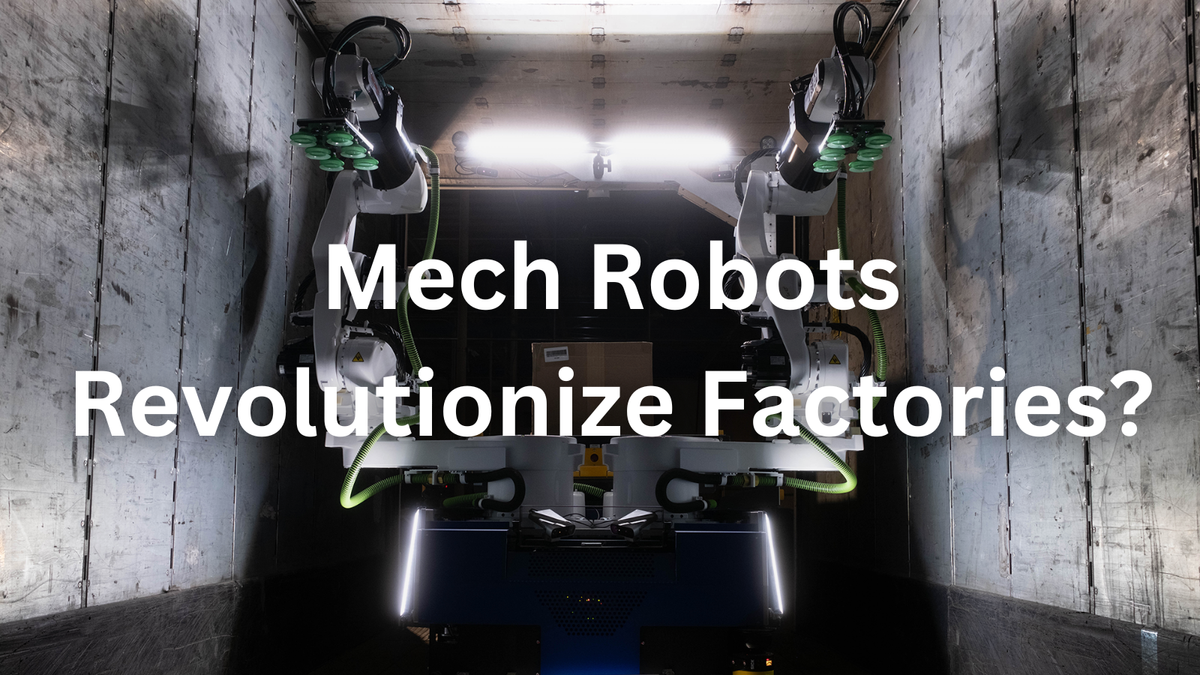

Manufacturing and logistics have long grappled with a critical challenge: how to handle repetitive, physically demanding tasks without sacrificing worker safety or efficiency. Enter Mech—the world's first AI-powered industrial super-humanoid robot that promises to rewrite the rules. Developed by California-based Dexterity, this 17-foot mechanical marvel can lift 132 pounds, work in extreme temperatures, and learn new skills overnight. But will it empower workers or make them obsolete? Let's dive in.

🤖 Meet Mech: The Superhuman Factory Partner

Dexterity's breakthrough isn't just another assembly-line bot. Mech combines human-like adaptability with machine precision through three revolutionary features:

- ✅ Physical AI Dominance: 16 cameras and hundreds of AI models enable real-time decision-making—like instantly adjusting grip strength for fragile items

- ✅ Extreme Environment Mastery: Operates in -0°F to 122°F ranges (perfect for freezer warehouses or foundries)

- ✅ Scalable Strength: 132-pound lifting capacity with millimeter precision, reaching 8-foot heights effortlessly

- ✅ 10x Productivity Boost: One worker can supervise 10 Mechs simultaneously, slashing injury risks from heavy lifting

🚀 The Logistics Game-Changer: From Warehouses to Loading Docks

Mech isn't just strong—it's smart. Its "superhumanoid" design tackles four critical operations:

- 📦 Palletizing/Depalletizing: Stack 130-pound boxes at 60+ units/hour with perfect balance

- 🚚 Truck Loading: Optimize space usage 30% better than human crews using AI spatial mapping

- 📦 Order Picking: 99.9% accuracy rate via object recognition (vs. human 95% average)

- 🔄 Future-Proof Skills: Software updates teach new tasks like quality inspection or machine maintenance

⚠️ The Human Factor: Enhancement vs. Replacement

While Mech's specs dazzle, real-world adoption faces three hurdles:

- 🚧 Job Security Fears: Can factories retrain workers as "robot supervisors" fast enough?

- 🚧 Technical Limits: 16-camera systems struggle in low-light environments (common in older warehouses)

- 🚧 Public Perception: 67% of manufacturing workers in a 2024 Pew survey feared automation would reduce jobs

🔮 The Future of Work: Collaboration, Not Competition?

Dexterity's vision hinges on Mech being a tool, not a replacement. Key indicators suggest:

- 📈 Success If: Factories use Mech for dangerous tasks (chemical handling, extreme heights)

- 📉 Failure Risk: Companies prioritize cost-cutting over worker retraining programs

- 🚀 Wild Card: Union negotiations could shape Mech's role—will operators demand "robot oversight" clauses?

As Mech rolls out to early adopters in 2026, one question looms: Will this superhumanoid create a new era of human-machine teamwork—or become the factory worker's obsolescence? The answer may define the next decade of manufacturing.

What's your take? Could you work alongside a 17-foot robot colleague, or does Mech spell trouble for blue-collar jobs? Let's discuss.

Let us know on X (Former Twitter)

Sources: Kurt Knutsson. World’s first AI-powered industrial super-humanoid robot, April 6, 2025. https://www.foxnews.com/tech/worlds-first-ai-powered-industrial-super-humanoid-robot